Maxim’s new Go-IO PLC reference design drives intelligence to the digital factory edge, enabling active monitoring and communication of equipment health and status information and enhancing throughput and productivity.

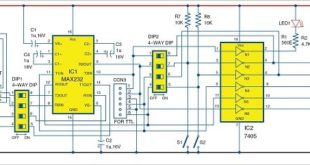

Implementing industrial IoT requires increasing the number of smart, connected sensors and PLCs within automated factories’ edge equipment. These PLCs must be small enough to fit on a sub-assembly line or a complex machine. The new Go-IO PLC reference design from Maxim Integrated suits these demands by providing 17 configurable IOs in a small form factor that is half the size of a credit card. This allows an unparalleled level of integration to address the needs of industrial automation, building automation, and industrial robotics applications.

“Digital factories can dynamically adjust the manufacturing line on the fly based on new or changing requirements. To fully realize industrial convergence, automated equipment must also possess self-diagnostic and optimization capabilities. Go-IO pushes intelligence closer to the edge, enabling active monitoring and communication of equipment health and status information as well as higher throughput and productivity”, Maxim noted.

Maxim’s Go-IO Drives Intelligence to the Digital Factory Edge

The design has 12 highly integrated ICs, 17 IOs supporting multiple digital IO configurations, a 4-channel IO-Link master to provide a universal IO interface to both analog and digital sensors, and a robust 25Mbps isolated RS-485 communications channel that provides a reliable, multi-drop data network for uploading time-sensitive health and status information into a local data lake or the cloud.

Key Advantages

- Increased Productivity: enriches automated factory equipment with real-time health and status information, so that factory equipment can quickly isolate and resolve problems to maintain high levels of uptime

- Decentralized Control: shifts control and intelligence from one central command center to each automated piece of equipment, enabling equipment to adapt on the fly to changes in product specifications or manufacturing needs

- Small Size, Low Power: packs more intelligence in a smaller footprint— claimed to be 10x smaller (at less than 1 cubic Inch) and 50 percent lower power than its predecessor

“As factories and manufacturing plants gather data from an increasing number of automated machines, the PLCs must be smaller to fit on a sub-assembly line or a complex machine. Go-IO furthers industrial convergence with a next-generation industrial IO solution that increases productivity and provides machine-level health and status information for making critical, real-time decisions,” said Jeff DeAngelis, managing director, Industrial & Healthcare Business Unit, at Maxim Integrated.

Availability and Pricing

The Go-IO is available as MAXREFDES212# at Maxim’s website for $495. The reference design consists of an application processor, baseboard and the Go-IO module.

© © Copyright 2018 – EFY Group

This content was originally published here.