The new process involves less cumbersome steps and works on surfaces such as skin or paper

Processing methods for printed electronics these days involves steps such as chemical bath to rinse away unwanted material, a hardening process to ensure layers don’t mix, or an extended bake to remove traces of organic material that can interfere with electric fields. Besides being cumbersome, these steps also inhibit their large scale implementation for various applications.

Processing methods for printed electronics these days involves steps such as chemical bath to rinse away unwanted material, a hardening process to ensure layers don’t mix, or an extended bake to remove traces of organic material that can interfere with electric fields. Besides being cumbersome, these steps also inhibit their large scale implementation for various applications.

To improve the current scenario, electrical engineers at Duke University have successfully developed a fully print-in-place technique for electronics that is gentle enough to work on delicate surfaces such as paper and human skin. Through this advancement, the engineers hope that this technology can be implemented for embedded electronic tattoos and biosensor-based bandages for medical patients.

“Over the years there have been a slew of research papers promising these kinds of ‘fully printed electronics,’ but the reality is that the process actually involves taking the sample out multiple times to bake it, wash it or spin-coat materials onto it.” said Aaron Franklin, Associate Professor of Electrical and Computer Engineering, Duke University Franklin. “Ours is the first where the reality matches the public perception.”

Previous flexible design

Earlier devised electronic tattoos were thin, flexible patches of rubber that contained flexible electrical components. The thin film stuck to skin much like a temporary tattoo and was effective in monitoring heart and brain. However, they’re not suited enough for direct surface modification by adding custom electronics.

Newer procesing method

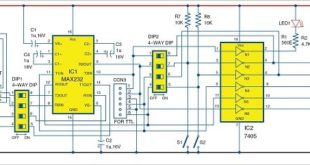

To develop the electronic tattoo, first, a novel ink was created that contained silver nanowires for printing onto any substrate at low temperatures with an aerosol printer. It produced a thin film that maintained its conductivity without any further processing. After being printed, the ink was dried for it to retain its high electrical performance (even after undergoing bending strain several times).

This print-in-place requires fewer steps and despite the need for each layer to dry completely to avoid mixing of materials, the overall procedure can be completed at a low processing temperature.

“For direct or additive printing to ever really be useful, you’re going to need to be able to print the entirety of whatever you’re printing in one step,” said Franklin. “Some of the more exotic applications include intimately connected electronic tattoos that could be used for biological tagging or unique detection mechanisms, rapid prototyping for on-the-fly custom electronics, and paper-based diagnostics that could be integrated readily into customized bandages.”

Can be used for prototyping

According to the developers, this printing method has the potential to be used for rapid prototyping or situations where one size doesn’t fit all.

“Think about creating bespoke bandages that contain electronics like biosensors, where a nurse could just walk over to a work station and punch in what features were needed for a specific patient,” said Franklin. “This is the type of print-on-demand capability that could help drive that.”

This content was originally published here.